NIKO Pneumatic Membrane Presses

NIKO has been manufacturing pneumatic presses, and solely pneumatic presses, since 1994. The unique features, wide array of options, and quality reflect this specialization. Manufactured in Slovenia, NIKO presses are used extensively in Germany and Austria. NIKO enlarged their production facility in 2006, thus allowing expansion outside Europe. St. Patrick's is the exclusive USA distributor.

Please compare the quality and features of NIKO presses with competitive brands.

-

Rotary Vane compressor on all units

-

For example, the maximum operational pressure is 1.7 bar compared to 1.5 bar for most competitive brands (this is due to compressor and/or strength of the doors).

-

We supply axial loading with large stainless ball valve on all units

-

We supply stainless valve on outlet of collection pan.

-

The vertical screen in collection pan is standard on NIKO presses.

-

The easy clean design of the doors is standard on all units.

-

Two doors is standard on VP8e and larger.

VP

- Available in 9 volumes: 11, 15, 21, 26, 32, 44, 52, 60 and 80 Hectoliter

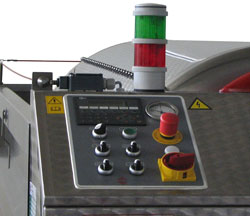

- AS automatic controls with 11 fixed programmed pressing cycles (7 red and white, sparkling, late harvest, 2 ice wine) and a program for axial loading and another for maceration. User can quickly change any parameter within each of these cycles. Additionally, user can add up to 20 additional programmed cycles. Digital display. Multicolored lights indicate state of operation.

- Separate Manual controls.

- Juice collection pan with vertical screen filter. Mounted on 4 pivoting wheels. TriClamp stainless Ball valve on outlet.

- Quiet rotary vane compressor (Becker).

- Two large sliding doors.

- Unique NIKO features

- Safety (interlock) cords are moveable on sides and fixed on end. Moveable cord allows easy access for cleaning.

- Upper and lower side panels are hinged for easy access during cleaning.

- Door design permits easy cleaning of underside of doors.

- Axial loading with TriClamp stainless steel Ball Valve.

- Cylinder rotates in both directions

- Membrane made of nontoxic material designed specifically for presses.

- Quiet fan for fast membrane inflation to 0.2 atm

- Quiet fan for deflation of membrane

- Muffler to mitigate noise

- 304 stainless steel construction

- 4 pivoting wheels with brakes

- 230 V, 3-phase power on all units

- 2 year warranty

please order before April 1

VP11 $28,800

VP15 $37,100

VP21 $43,100

VP26 $45,400

VP32 $51,800

VP44 $62,600

VP52 $74,900

VP60 $83,900

VP Options

- Sensor with alarm indicating when press is full (axial loading)

- Leg extensions (to place half-ton macrobin under cylinder to collect pomace)

- Platform

- Hopper for whole grape loading from macrobin

- Non-perforated doors for maceration.

- Plugs for drain channels. Used in conjunction with non-perforated doors for maceration.

- Water proof sliding doors

- Sliding juice collection pan. Pan slides in/out on rails (guides) as needed for cleaing and pressing.

- Level switch in collection tray

- Pneumatic drive for doors

- Detachable control box with cable

VPe

- Available in 5 volumes: 5, 8, 11, 15, 21 Hectoliter

- AE automatic controls with 4 fixed programmed pressing cycles, axial loading progam, maceration program, and 2 programmable pressing cycles.

- Separate Manual controls.

- Juice collection pan with vertical screen filter. Mounted on 4 pivoting wheels. TriClamp stainless Ball valve on outlet.

- Quiet rotary vane compressor (Becker).

- Safety (interlock) cords are fixed on sides and end.

- Fixed side panels without hinges.

- Large doors. VPe8, 11, 15, 21 with two sliding doors. VPe5 has one door.

- Unique NIKO feature. Door design permits easy cleaning of underside of doors.

- Axial loading with TriClamp stainless steel Ball Valve.

- Cylinder rotates in both directions (3 phase motors)

- Membrane made of nontoxic material designed specifically for presses.

- Quiet fan for fast membrane inflation to 0.2 atm

- Quiet fan for deflation of membrane

- Muffler to mitigate noise

- 304 stainless steel construction

- 4 pivoting wheels with brakes

- 230 V, 3-phase for VP11e, VP15e, and VP21e.

- 230 V, 1-phase for VP5e and VP8e.

- 2 year warranty

VP5e-single phase $17,800 sold out

VP8e--single phase $19,700 sold out

VP11e $23,100 sold out

VP15e $29,200 please order before April 1

VP21e $34,500 please order before April 1

Also, one side is hinged for easier cleaning as in VP models.

VPe Options

- Sensor with alarm indicating when press is full (axial loading)

- Leg extensions (to place half-ton macrobin under cylinder to collect pomace)

- Platform

- Hopper for whole grape loading from macrobin (VP11 and larger)

- Non-perforated doors for maceration (this also requires different drain channels than perforated cylinder)

- Plugs for drain channels. Used in conjunction with non-perforated doors for maceration.

- Sliding juice collection pan. Pan slides in/out on rails (guides) as needed for cleaing and pressing.

- Level switch

Replacement membranes

We stock replacement membranes and encourage users to keep an extra on hand. The most common cause of punctures is pruning shears in whole grapes but wire and nails can make their way through destemmers/pumps as well. It takes two people about 1-2 hours to change a membrane. NIKO membranes are easier to change than most.

VP5 membrane $600

VP8 membrane $675 out of stock

VP11 membrane $720

VP15 membrane $770

VP21 membrane $940

VP26 membrane $1000

VP32 membrane $1080

VP44 membrane $1150

VP52 membrane $1250

Includes extension for both press and the juice pan.

VP5/8/11 $800

VP15 $900 order before April 1

VP21/26 $900 order before April 1

VP32/44 $1000 order before April 1

VP52/60 $1200 order before April 1

Hopper (for dumping whole fruit)

VP15/21 $2100

VP26 $2300

VP32 $2500

VP44 $3100

VP52 $3600

VP60 $4100