MEP is a family business founded in 2002.

All MEP machines are designed, engineered, constructed, and tested entirely in-house. This is what separates MEP.

St. Patrick's has been the EXCLUSIVE importer and authorized distributor of MEP in North America since 2003, over 21 years.

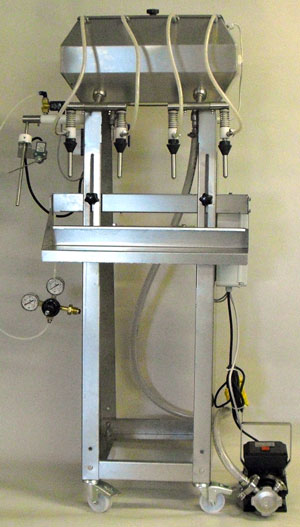

MEP FILLING MACHINE with ELECTRONIC Float Control and Gas SPARGER

Complete with Pump and N2 regulator.

Highest quality filler for small wineries and distilleries

The ONLY filler with built-in Sparger and regulator

Electronic Level Control with Pump

Floor model on Wheels

Pump will turn on and off to fill tank as needed.

Microswitch opens N2 sparge valve.

Fill automatically stops at preset level.

Filler with MEP-20 FIP Pump $4095 ![]() in stock in Taylor

in stock in Taylor

230 V, single phase. Best for wine.

Filler with Jet05 Centrifugal Pump $3795 ![]() in stock in Taylor

in stock in Taylor

110 V. Best for spirits.

- Electronic Level Control. Turns pump On/Off as needed to fill tank.

- Gas Sparger w/ N2 regulator, 15-25 psi

- 4 Nozzles

- 600 bottles/hour

- 110 V Jet05 pump or 220 V MEP-20 FIP pump (with 1.5" Triclamp inlet/outlets)

- Floor unit, 4 wheels

- Precise adjustable control of fill level.

- Automatic shut off when bottle is full. Each spout operates independently

- Reservoir capacity ~9 gallons

- Bottle heights 7"-20"

- 304 Stainless Steel

- Dimensions: 28"x21"x61" LxWxH

Nozzle for Long Neck Bottle $250 each ![]()

If fill level of your bottle is greater than 3-1/4" below the top of the bottle, you will need this nozzle. If you are uncertain, please send us drawing of the bottle.

Nozzle for Mignon (airplane) Bottle $250 each ![]()

50 cc, aka mignon, or airplane bottles.

Bottle must have a long neck like

a wine bottle.

You cannot have suspended particles

that will plug the nozzles.

4-Spout Floor with Electronic Float Control and Gas Sparger, N2 regulator, and MEP-20 pump.

Operation of this filling machine is nearly self-evident but here's a quick summary

- The fill nozzles are spring-loaded valves. Push the bottle onto the nozzle firmly to open the valve and begin filling. Filling will shut off automatically when the preset fill level is reached.

- The bottles rest on an adjustable tray. This tray is moved to accomodate bottles from 7" to 20" height.

- Fill level: Loosen the allen screw on the nozzle bushing and raise or lower the bushing to adjust the fill level. Do not overtighten the allen screw. It is simply snugged up to hold the bushing in position.

- Set regulator at 25 psi. (sparge for ~2 seconds)

- Tip on setup : Ignore the tray and Adjust Fill level first. Then position tray at HIGHEST possible position.